Products / Order Picking and Processing

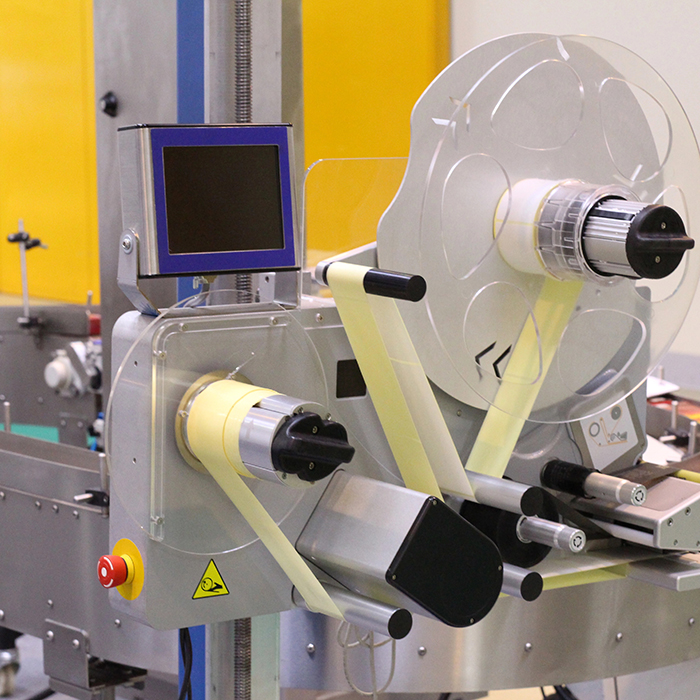

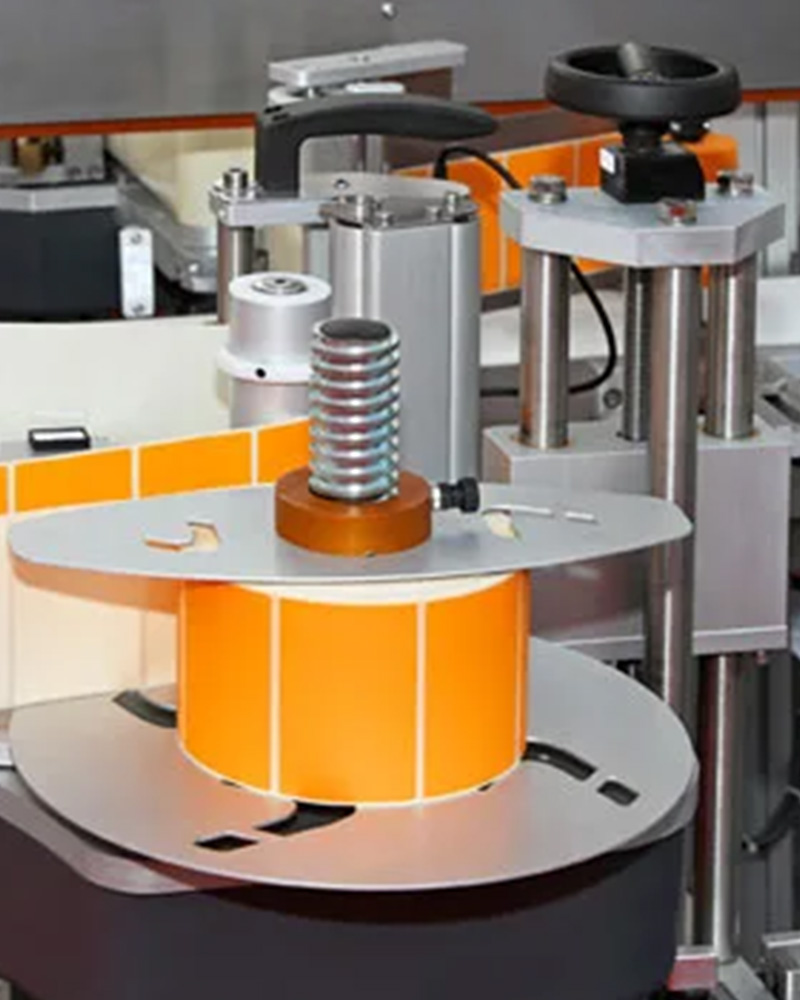

Automatic labeling machines are devices that are designed to apply labels to products or packages quickly and accurately. These machines are widely used across an array of industries.

Automatic labeling machines are devices that are used in the process of labeling products for identification, tracking, and inventory management purposes. These machines automate the labeling process, eliminating the need for manual labeling, which can be time-consuming and error-prone.

The types of bar code labels that can be produced by automatic labeling machines include:

UPC (Universal Product Code) labels: These are the most common bar code labels used in retail stores to identify products.

EAN (European Article Number) labels: These are similar to UPC labels but are used more widely in Europe and other parts of the world.

Code 39 labels: These bar code labels are commonly used in logistics and supply chain management to track products through the distribution process.

Code 128 labels: These bar code labels are used for more complex applications such as tracking products through the manufacturing process and for inventory management.

QR code labels: These are two-dimensional bar code labels that can store more data than traditional one-dimensional bar codes. They are commonly used in marketing and advertising campaigns.

Increased efficiency: Automatic labeling machines can label products much faster than manual labeling, resulting in increased production and throughput.

Reduced labor costs: By automating the labeling process, companies can reduce the number of workers needed to label products, resulting in cost savings.

Improved accuracy: Automatic labeling machines can apply labels with precision, reducing errors and ensuring that the correct label is applied to each product.

Enhanced traceability: Bar code labels applied by automatic labeling machines enable companies to track products through the supply chain, improving inventory management and reducing the risk of lost or stolen products.

Customizability: Automatic labeling machines can be programmed to produce labels with different information and formats, allowing companies to customize labels to meet their specific needs.

Increased safety: By eliminating the need for manual labeling, automatic labeling machines can improve worker safety by reducing the risk of injury associated with repetitive labeling tasks.

Customers rely on LD Systems because we are the best. Terms like ROI, Data Analysis, and Optimization are what we live every day.

Our integrated solutions are among the industry’s most trusted because we tackle each distribution center optimization project through a comprehensive discovery process that includes analyzing data, price points and anticipated return on investment. It’s only then our team begins to develop the perfect layout with flexibility and scalability.

With a combined 50 years of material handling integration experience, we are the experts at maximizing efficiency and moving goods expeditiously from order to door. LD Systems is your logical choice.

Contact us to learn more about Automatic Labeling Machines or other sortation equipment.

Unlock your warehouse’s potential with LD Systems. We want to understand your goals, pain points and challenges. Request your free, no-obligation consultation and one of our Integration Solutions Specialist will reach out.

1500 Beville Rd, Suite 606-221

Daytona Beach, FL 32114